What’s the deal with Connell chain?

The Connell chain is a revolutionary technology that has gained significant attention in various industries. This article explores the history, functionality, benefits, applications, challenges, and future developments of the Connell chain. Read on to discover how this innovative chain system is transforming industries and what the future holds for its advancements.

Key Takeaways

- The Connell chain is a groundbreaking technology with diverse applications in industries such as automotive, construction, and food.

- It offers numerous benefits, including increased efficiency, improved safety, and reduced maintenance requirements.

- However, the Connell chain also faces challenges such as maintenance and durability issues, cost considerations, and integration challenges.

- Future developments in the Connell chain include improved materials and designs, automation and robotics integration, and utilization of IoT and data analytics.

- Overall, the Connell chain is a promising technology that is set to revolutionize various industries and pave the way for enhanced productivity and innovation.

What is the Connell chain?

The history of the Connell chain

The Connell chain has a rich history that dates back to the early 20th century. It was first developed by John Connell, a mechanical engineer, who recognized the need for a reliable and efficient chain system. The Connell chain revolutionized various industries by providing a robust and durable solution for transmitting power and motion.

One of the key milestones in the history of the Connell chain was its adoption in the manufacturing sector. The chain's ability to handle heavy loads and withstand harsh operating conditions made it an ideal choice for assembly lines and conveyor systems. This led to increased productivity and efficiency in factories, paving the way for industrial automation.

Another significant development in the history of the Connell chain was its application in the transportation industry. The chain's strength and reliability made it suitable for use in vehicles, such as motorcycles and bicycles, ensuring smooth and consistent power transmission. This contributed to improved performance and safety on the roads.

Overall, the history of the Connell chain is marked by continuous innovation and its widespread adoption across various industries.

How does the Connell chain work?

The Connell chain operates on a simple yet effective principle. It consists of a series of interconnected links that form a continuous loop. Each link has a unique design that allows it to smoothly engage with the adjacent links, creating a seamless motion. The chain is driven by a motor or an external force, which causes the links to move in a synchronized manner.

One of the key features of the Connell chain is its ability to transmit power and motion efficiently. The links are designed to minimize friction and maximize contact area, ensuring smooth and reliable operation. This makes the Connell chain ideal for applications that require precise and continuous motion, such as conveyor systems and robotic arms.

To ensure the longevity of the chain, regular maintenance is essential. Lubrication and periodic inspections help prevent wear and tear, ensuring optimal performance. Additionally, the chain should be protected from excessive loads and harsh environments to avoid premature failure.

In summary, the Connell chain is a versatile and reliable mechanism that enables efficient power transmission and motion. Its unique design and robust construction make it suitable for a wide range of applications in various industries.

Benefits of using the Connell chain

Using the Connell chain offers several advantages in various industries:

-

Increased efficiency: The Connell chain's design allows for smooth and reliable movement, reducing downtime and improving productivity.

-

Enhanced durability: With its high-quality materials and robust construction, the Connell chain can withstand heavy loads and harsh environments.

-

Cost savings: The long lifespan and low maintenance requirements of the Connell chain result in reduced operational costs over time.

-

Versatility: The Connell chain can be customized to fit different applications and requirements, making it suitable for a wide range of industries.

Tip: Regular inspections and proper lubrication can further extend the lifespan of the Connell chain.

Applications of the Connell chain

Connell chain in the automotive industry

The Connell chain has found numerous applications in the automotive industry. One of the key areas where it is used is in the assembly line process. The Connell chain's durability and strength make it ideal for carrying heavy components and ensuring smooth movement along the production line.

In addition, the Connell chain is also used in conveyor systems within automotive manufacturing plants. These conveyor systems transport various parts and components throughout the facility, ensuring efficient and streamlined production processes.

Furthermore, the Connell chain is utilized in the suspension systems of vehicles. Its ability to withstand high loads and provide reliable performance makes it a preferred choice for ensuring stability and safety in automotive suspensions.

Overall, the Connell chain plays a crucial role in enhancing productivity, efficiency, and reliability in the automotive industry.

Connell chain in the construction industry

The Connell chain has found numerous applications in the construction industry due to its durability and strength. It is commonly used for heavy lifting and transporting materials on construction sites. The chain's robust design allows it to withstand the demanding conditions of construction environments, making it a reliable choice for various tasks.

One of the key advantages of using the Connell chain in construction is its ability to handle heavy loads. With its high tensile strength, the chain can support the weight of large construction materials, such as steel beams and concrete blocks. This makes it an essential tool for lifting and moving heavy objects safely and efficiently.

In addition to its strength, the Connell chain is also known for its resistance to corrosion. Construction sites often expose chains to harsh weather conditions and corrosive substances. The Connell chain's corrosion-resistant properties help to prolong its lifespan and ensure its reliability in construction projects.

To ensure the optimal performance of the Connell chain in construction, regular maintenance is essential. This includes lubricating the chain, inspecting for any signs of wear or damage, and replacing worn-out components. Proper maintenance can help prevent unexpected failures and extend the chain's lifespan, reducing downtime and increasing productivity on construction sites.

Overall, the Connell chain is a valuable asset in the construction industry, providing durability, strength, and resistance to corrosion. Its ability to handle heavy loads and withstand harsh conditions makes it an indispensable tool for construction projects of all sizes.

Connell chain in the food industry

The Connell chain has found numerous applications in the food industry due to its durability and reliability. One of the key areas where the Connell chain is used is in conveyor systems for transporting food products. The chain's strong and sturdy construction ensures smooth and efficient movement of goods, reducing the risk of damage or contamination.

In addition to conveyor systems, the Connell chain is also utilized in food processing equipment. It is commonly used in machines such as mixers, slicers, and packaging systems. The chain's ability to withstand heavy loads and high-speed operation makes it ideal for these applications.

Furthermore, the Connell chain's corrosion-resistant properties make it suitable for use in environments where food products are exposed to moisture or chemicals. This ensures that the chain remains in optimal condition and maintains its performance over time.

Overall, the Connell chain plays a crucial role in the food industry by providing reliable and efficient solutions for transportation and processing of food products.

Challenges and limitations of the Connell chain

Maintenance and durability issues

Maintenance and durability are key considerations when using the Connell chain. Due to its complex design and multiple moving parts, regular maintenance is required to ensure optimal performance. This includes lubrication, inspection, and replacement of worn components. Additionally, the durability of the chain can be affected by factors such as heavy loads, harsh environments, and improper usage.

To address these issues, manufacturers are constantly working on improving the materials used in the Connell chain. This includes the development of stronger and more resistant alloys that can withstand higher loads and harsher conditions. Furthermore, advancements in design and manufacturing processes aim to enhance the overall durability and reliability of the chain.

It is important for users of the Connell chain to carefully consider the maintenance requirements and durability limitations in their specific applications. Regular inspections and proactive maintenance can help prevent unexpected failures and ensure the longevity of the chain. Additionally, proper training and adherence to usage guidelines can minimize the risk of premature wear and damage.

Table: Maintenance and Durability Considerations

| Consideration | Description |

|---|---|

| Regular maintenance | Lubrication, inspection, and component replacement |

| Durability factors | Heavy loads, harsh environments, improper usage |

| Material improvements | Stronger alloys, resistance to higher loads and harsh conditions |

| Design and manufacturing advancements | Enhanced durability and reliability |

Tip: Regular maintenance and proper usage guidelines are essential for maximizing the lifespan of the Connell chain.

Cost considerations

When considering the use of the Connell chain, it is important to take into account the associated costs. The initial investment in implementing the Connell chain system may be higher compared to traditional chain systems. However, it is important to note that the Connell chain offers several long-term cost-saving benefits.

One of the main cost-saving benefits of the Connell chain is its durability. The Connell chain is designed to withstand heavy loads and harsh environments, reducing the need for frequent replacements and repairs. This can result in significant cost savings over time.

Additionally, the Connell chain's efficient design and smooth operation can contribute to energy savings. The reduced friction and improved performance of the chain can lead to lower energy consumption, resulting in reduced operational costs.

It is also worth considering the potential cost savings in terms of maintenance. The Connell chain requires less maintenance compared to traditional chain systems, reducing the need for regular inspections and repairs. This can result in reduced downtime and increased productivity.

In summary, while the initial investment in implementing the Connell chain system may be higher, the long-term cost-saving benefits, including durability, energy savings, and reduced maintenance, make it a cost-effective choice for many industries.

Integration challenges

Integration challenges are one of the key considerations when implementing the Connell chain in various industries. The complex nature of the chain and its components can make integration with existing systems and processes a challenging task. Compatibility with different equipment and machinery is crucial to ensure seamless operation. Additionally, coordination between different stakeholders involved in the integration process is essential to avoid delays and errors.

To overcome these challenges, organizations may need to invest in customization and adaptation of the Connell chain to fit their specific requirements. This may involve modifying existing equipment or developing new interfaces to enable smooth integration. Testing and validation of the integrated system are also critical to ensure reliability and performance.

In some cases, organizations may choose to seek assistance from specialized consultants or service providers who have expertise in Connell chain integration. These professionals can provide valuable insights and guidance throughout the integration process, helping organizations overcome challenges and maximize the benefits of using the Connell chain.

Future developments and advancements in the Connell chain

Improved materials and designs

Advancements in materials and designs have played a crucial role in enhancing the performance and durability of the Connell chain. Manufacturers have focused on developing high-strength alloys and wear-resistant coatings to improve the chain's resistance to corrosion and abrasion. Additionally, innovative designs, such as reduced friction links and self-lubricating mechanisms, have been introduced to minimize energy loss and increase efficiency.

In terms of materials, a recent study comparing different alloys used in the Connell chain found that titanium alloys exhibited superior strength and durability compared to traditional steel alloys. This finding has led to increased interest in exploring the use of titanium alloys in the manufacturing of Connell chains.

Furthermore, advancements in design have led to the development of modular chain systems, allowing for easier installation, maintenance, and customization. These modular systems enable quick replacement of individual chain links, reducing downtime and improving overall productivity.

Overall, the continuous improvement in materials and designs has significantly contributed to the reliability and performance of the Connell chain, making it a preferred choice in various industries.

Automation and robotics in Connell chain systems

Automation and robotics play a crucial role in the implementation of Connell chain systems. These advanced technologies enable efficient and precise control over the movement and operation of the chain, resulting in improved productivity and safety.

One of the key advantages of automation in Connell chain systems is the ability to automate repetitive tasks, reducing the need for manual labor and increasing overall efficiency. Robots can be programmed to perform tasks such as loading and unloading materials, assembling components, and inspecting the chain for defects.

Additionally, automation allows for real-time monitoring and data collection, providing valuable insights into the performance and condition of the chain. This data can be used for predictive maintenance, identifying potential issues before they lead to costly downtime.

In summary, automation and robotics in Connell chain systems offer enhanced productivity, safety, and data-driven decision-making.

Integration with IoT and data analytics

The integration of the Connell chain with IoT and data analytics opens up new possibilities for optimizing operations and improving efficiency. By connecting the chain to sensors and collecting real-time data, businesses can gain valuable insights into the performance and condition of the chain.

Benefits of integrating Connell chain with IoT and data analytics:

- Real-time monitoring: IoT-enabled sensors can provide continuous monitoring of the chain's performance, allowing for proactive maintenance and minimizing downtime.

- Predictive maintenance: Data analytics can analyze the collected data to identify patterns and predict potential issues, enabling timely maintenance and reducing costly breakdowns.

- Optimized operations: By analyzing the data, businesses can identify areas for improvement and optimize the use of the Connell chain, leading to increased productivity and cost savings.

Tip: Regularly analyze the data collected from the integrated Connell chain to identify trends and make data-driven decisions for continuous improvement.

Conclusion

In conclusion, the Connell chain is a fascinating concept that has the potential to revolutionize the way we think about supply chains. With its innovative features and benefits, such as increased transparency and efficiency, the Connell chain has the power to transform industries and improve the lives of people around the world. As businesses continue to adopt this technology, we can expect to see significant advancements in supply chain management. It is an exciting time for the Connell chain, and we look forward to witnessing its impact in the years to come.

Frequently Asked Questions

What is the Connell chain?

The Connell chain is a type of chain used in various industries for applications such as conveying, lifting, and transferring heavy loads. It is known for its strength, durability, and flexibility.

How does the Connell chain work?

The Connell chain consists of interconnected links that form a continuous loop. It is driven by sprockets or pulleys, which rotate to move the chain. The links are designed to interlock and engage with the sprockets, allowing the chain to move smoothly and efficiently.

What are the benefits of using the Connell chain?

Using the Connell chain offers several benefits, including high load capacity, reliable performance, resistance to wear and corrosion, and the ability to handle heavy-duty applications. It is also customizable and can be tailored to specific requirements.

In which industries is the Connell chain commonly used?

The Connell chain finds applications in various industries, including the automotive industry, construction industry, food industry, and many others. It is used for tasks such as material handling, assembly line operations, and transportation of goods.

What are the challenges and limitations of the Connell chain?

Some challenges and limitations of the Connell chain include maintenance and durability issues, cost considerations, and integration challenges with existing systems. Regular inspection and maintenance are required to ensure optimal performance and longevity.

What are the future developments and advancements in the Connell chain?

The future of the Connell chain involves advancements in materials and designs to enhance strength and durability. Automation and robotics are also being integrated into Connell chain systems to improve efficiency and productivity. Additionally, the integration of IoT (Internet of Things) and data analytics is expected to enable real-time monitoring and predictive maintenance.

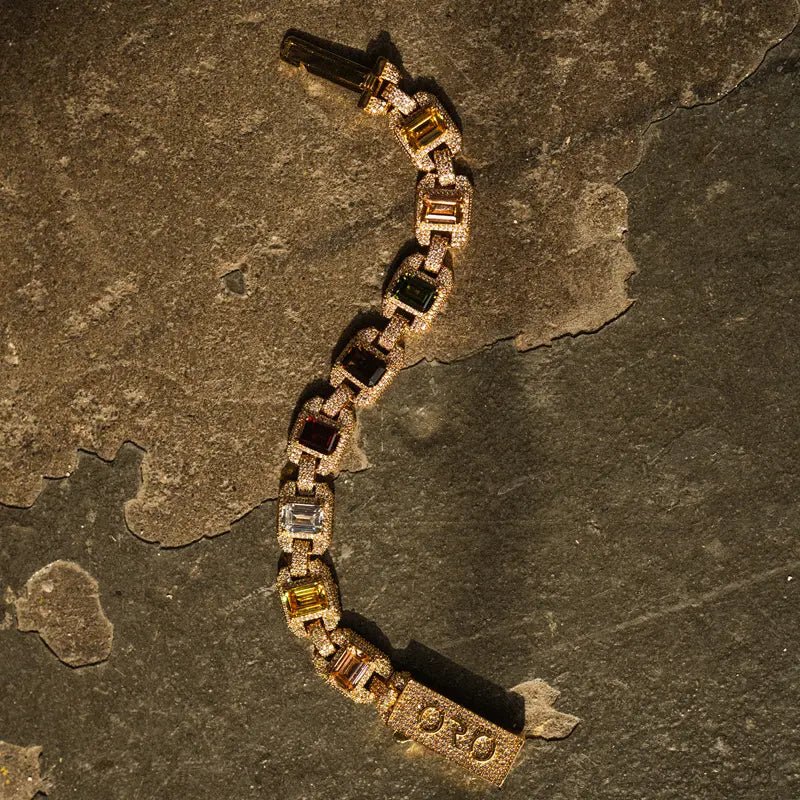

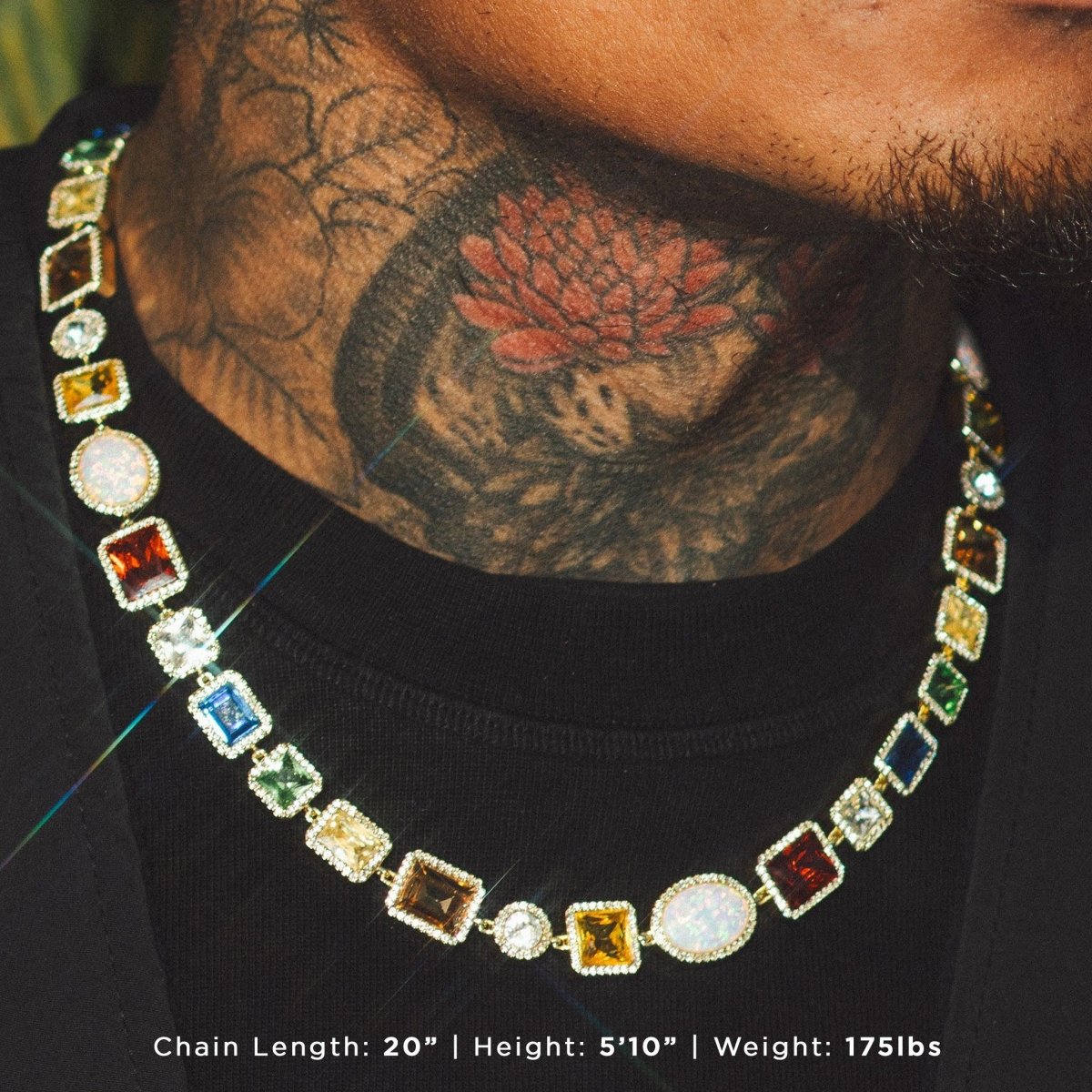

Best Sellers

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.