Are Rope Chains strong?

Rope chains are a popular choice for jewelry and other applications, but their strength and durability are often a topic of discussion. In this article, we will explore the factors that contribute to the strength of rope chains and how different types and materials affect their performance. Understanding the key takeaways will help you make informed decisions when choosing and caring for rope chains.

Key Takeaways

- Material composition plays a significant role in the strength of rope chains.

- Twisted rope chains offer a unique aesthetic but may be less durable than braided or diamond-cut chains.

- Regular cleaning and proper storage can extend the lifespan of rope chains.

- The weight-bearing capacity of a rope chain is influenced by its material quality and manufacturing process.

- Inspecting rope chains for stress points and wear is essential for preventing breakage.

Strength of Rope Chains

Material Composition

Rope chains are typically composed of twisted or braided strands of metal, such as gold, silver, or platinum. The composition of the rope chain determines its flexibility, strength, and overall appearance. Different materials may offer varying levels of tensile strength and resistance to corrosion.

It's important to consider the alloy composition and purity of the metal used in rope chains. Higher purity metals often exhibit greater durability and resistance to tarnishing. Additionally, the thickness and density of the metal strands contribute to the chain's weight-bearing capacity and longevity.

Material Composition Considerations

- Alloy composition

- Purity of metal

- Thickness and density of metal strands

Tip: Choose a material composition that aligns with your desired balance of strength, flexibility, and aesthetic appeal.

Weight Bearing Capacity

The weight bearing capacity of rope chains is a crucial factor in determining their suitability for various uses. Material composition plays a significant role in determining the strength of the chain, with materials like stainless steel and titanium offering high tensile strength. Durability is also essential, as chains made from durable materials are better equipped to withstand heavy loads and prolonged use.

When considering the weight bearing capacity of rope chains, it's important to evaluate the material composition and durability. These factors directly impact the chain's ability to bear weight and resist damage. Additionally, regular inspections and maintenance can help ensure that the chain remains strong and reliable over time.

Tip: Avoid exceeding the weight bearing capacity specified for the chain, as this can lead to deformation or breakage, compromising safety and functionality.

Durability

Rope chains are designed to withstand various environmental conditions and everyday wear. The material composition and construction play a crucial role in determining the durability of rope chains. Regular inspections and proper maintenance are essential for preserving the integrity of the chain.

- Material Composition: The type of material used in the rope chain significantly impacts its durability. Stainless steel and high-quality alloys are known for their resilience.

- Weight Bearing Capacity: Consider the weight-bearing capacity of the chain in relation to its intended use. Exceeding the recommended weight limit can compromise the durability of the chain.

- Usage Conditions: Factors such as exposure to moisture, chemicals, and extreme temperatures can affect the longevity of the rope chain.

Tip: Store rope chains in a dry, cool place to prevent corrosion and minimize stress on the chain during storage.

Types of Rope Chains

Twisted Rope Chains

Twisted Rope Chains are known for their strength and flexibility. The twisting pattern of the links provides added resilience and reduces the risk of kinking or tangling. When considering a Twisted Rope Chain, it's important to assess the material quality and manufacturing process to ensure optimal durability and load-bearing capacity. Here are some key considerations:

- Material Quality: Look for high-quality materials such as sterling silver or 14k gold to ensure longevity and strength.

- Manufacturing Process: Seek out chains that are crafted with precision and attention to detail, as this directly impacts the chain's ability to withstand stress and pressure.

Tip: Regularly inspect and clean your Twisted Rope Chain to maintain its strength and appearance. Avoid exposing it to harsh chemicals or extreme temperatures to prolong its lifespan.

Braided Rope Chains

Braided rope chains are known for their flexibility and intricate design. They are made by weaving multiple strands of material together, creating a strong and visually appealing chain. The braided structure enhances the durability and resistance to twisting of the chain, making it suitable for everyday wear. When comparing braided rope chains, consider the number of strands and the material used for braiding. Here's a table to illustrate the comparison:

| Chain Type | Number of Strands | Material |

|---|---|---|

| Braided A | 3 | Gold |

| Braided B | 5 | Silver |

Remember to store braided rope chains carefully to avoid tangling, and inspect them regularly for any signs of wear or damage. Proper care will ensure the longevity of these elegant chains.

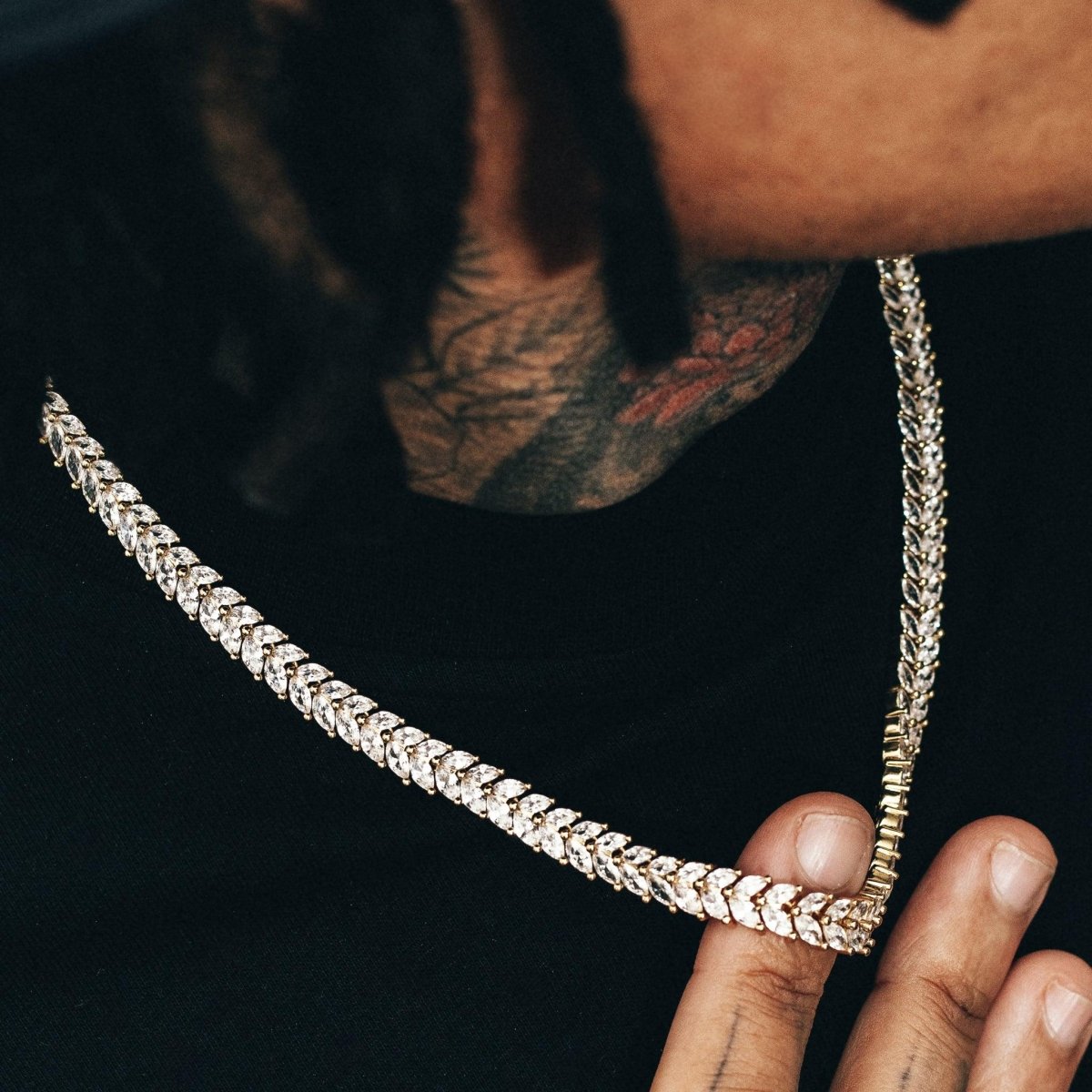

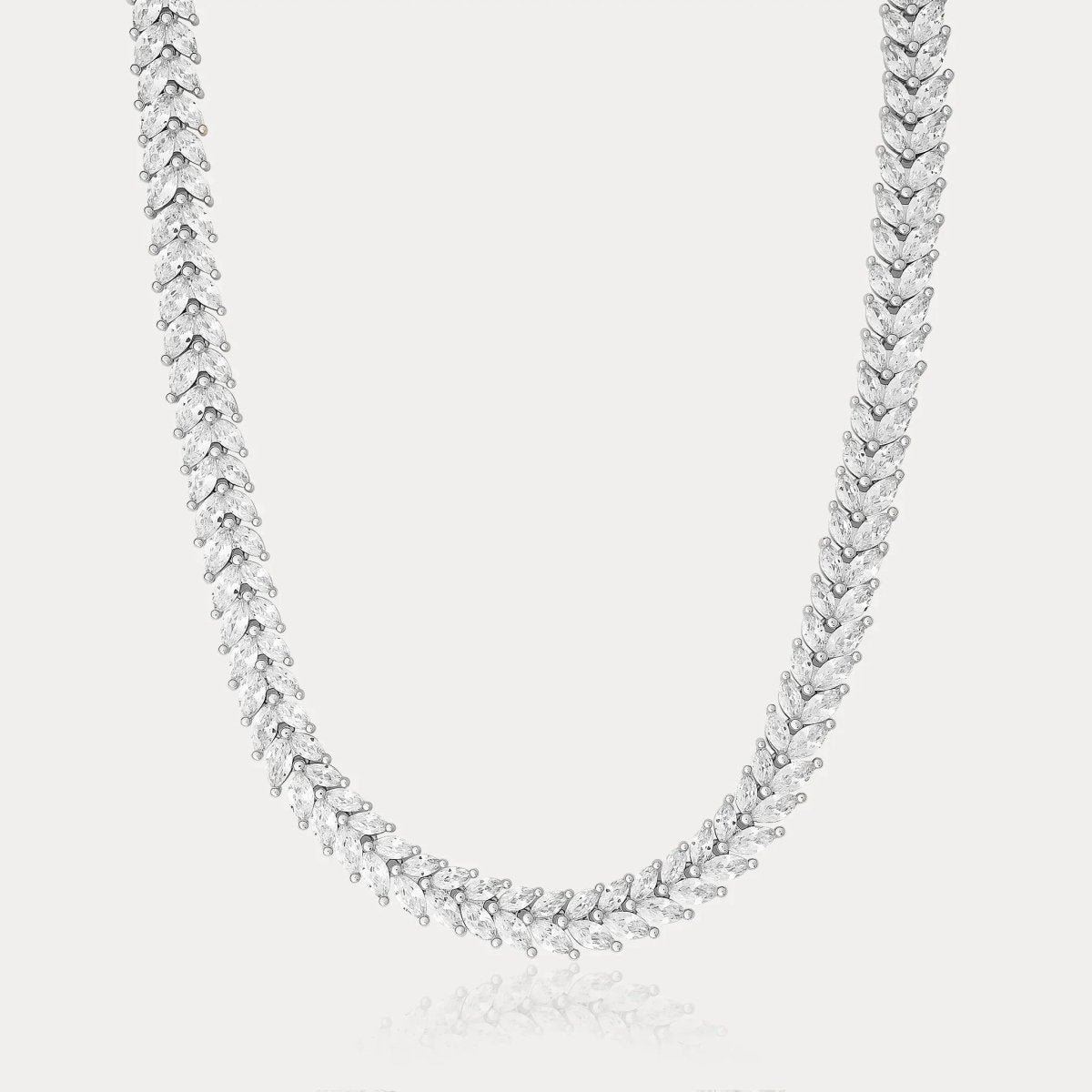

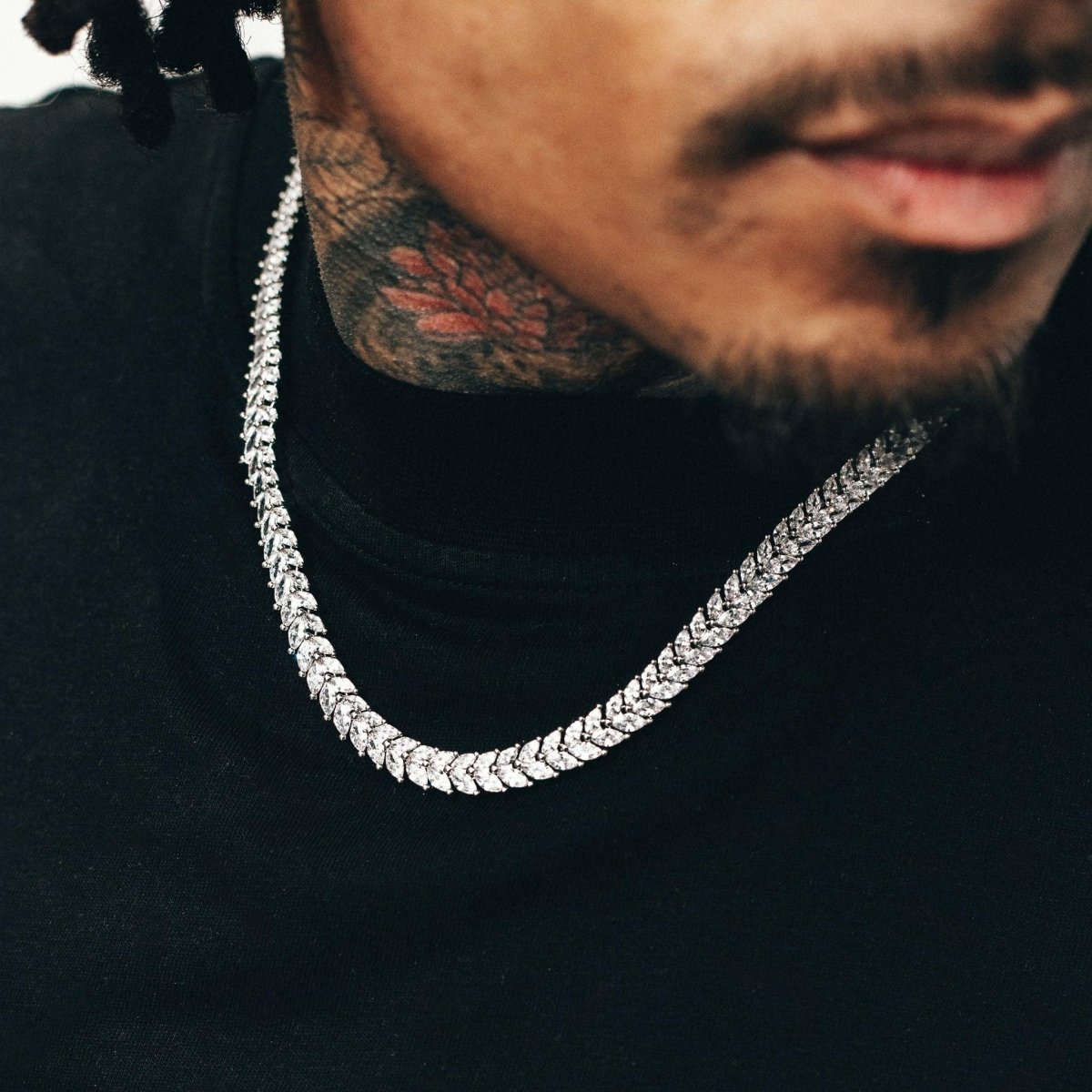

Diamond-Cut Rope Chains

Diamond-Cut Rope Chains are intricately designed with faceted surfaces that create a stunning play of light. These chains are known for their sparkling appearance and are often favored for their elegant and luxurious look. When considering a Diamond-Cut Rope Chain, it's important to note that the intricate design may slightly reduce the chain's overall strength compared to other types. However, the visual appeal and unique style make them a popular choice for those seeking a sophisticated and eye-catching accessory.

- Faceted surfaces create stunning play of light

- Known for sparkling appearance

- Elegant and luxurious look

Tip: Due to the intricate design, Diamond-Cut Rope Chains may require gentle handling to maintain their integrity and shine. Regular inspections and careful storage can help preserve their beauty and durability*.

Factors Affecting Rope Chain Strength

Material Quality

Material quality is a crucial factor in determining the strength and durability of rope chains. High-quality materials such as stainless steel and sterling silver contribute to the overall robustness of the chain. Inferior materials may compromise the chain's integrity and increase the risk of breakage.

It's important to consider the purity and grade of the materials used in the chain. Higher purity and superior grade materials are more resistant to corrosion, tarnishing, and deformation, ensuring the longevity of the rope chain.

When assessing material quality, it's advisable to refer to the manufacturer's specifications for detailed information on the composition and properties of the materials. This can provide valuable insights into the chain's performance and suitability for specific usage conditions.

Additionally, conducting regular inspections of the chain's material quality can help identify any signs of wear, damage, or degradation. This proactive approach can prevent potential issues and maintain the chain's strength over time.

Manufacturing Process

The manufacturing process plays a crucial role in determining the strength of rope chains. It involves the method of assembling and shaping the chain, which directly impacts its structural integrity and load-bearing capacity. The quality of materials used, such as alloys and treatments, during the manufacturing process significantly influences the overall strength and durability of the rope chain.

- Alloys: Different alloys used in the manufacturing process can result in varying degrees of strength and flexibility.

- Treatments: Heat treatments and surface finishes can enhance the resistance to wear and tear, contributing to the longevity of the rope chain.

Tip: Pay attention to the manufacturing details provided by the supplier or manufacturer to understand the specific processes and materials used, which can give insights into the strength and quality of the rope chain.

Usage Conditions

Material Quality, Manufacturing Process, and Usage Conditions are critical factors that impact the strength of rope chains.

Material quality refers to the purity and strength of the materials used in the chain, influencing its overall durability and resilience.

The manufacturing process plays a crucial role in determining the integrity and consistency of the chain, affecting its ability to withstand stress and pressure.

Usage conditions encompass the environment and circumstances in which the rope chain is utilized, including exposure to moisture, heat, and mechanical stress.

For a more detailed understanding, refer to the following table:

| Factor | Impact |

|---|---|

| Material Quality | Purity and strength of materials |

| Manufacturing Process | Integrity and consistency |

| Usage Conditions | Environment and circumstances |

Remember to regularly inspect and maintain your rope chain to ensure its longevity and reliability.

Maintenance and Care of Rope Chains

Cleaning and Storage

Proper cleaning and storage are crucial for maintaining the integrity of rope chains. Regularly cleaning the chain with a mild soap and warm water helps remove dirt and debris, preventing abrasion and corrosion. After cleaning, ensure the chain is completely dry before storing it to prevent moisture-related damage.

-

Avoiding stress points is essential for prolonging the lifespan of rope chains. Carefully handle the chain to prevent kinking or tangling, and store it in a way that minimizes contact with hard surfaces or sharp objects.

-

Regular inspections are recommended to identify any signs of wear or damage. Check for loose links, worn areas, or discoloration, and address any issues promptly to prevent further deterioration.

Tip: When storing rope chains, consider using soft fabric pouches or lined jewelry boxes to protect them from scratches and tangling. Avoid storing them in direct sunlight or humid environments to maintain their condition.

Avoiding Stress Points

Avoiding stress points is crucial for maintaining the integrity of rope chains. Excessive tension and sharp bends can weaken the chain over time. To prevent stress points, it's important to ensure that the chain is not subjected to sudden jerks or extreme twisting. Additionally, regular inspection for signs of wear and tear can help identify potential stress points early. Consider the following tips to minimize stress points:

- Even Distribution: Ensure that the weight or tension is evenly distributed along the chain to avoid localized stress.

- Proper Storage: Store the chain in a way that prevents kinks and tangles, reducing the risk of stress points during handling.

- Avoid Abrupt Movements: Handle the chain with care, avoiding sudden movements or sharp bends that can create stress points.

Tip: Regularly inspect the chain for any signs of kinking, twisting, or deformation, and address any issues promptly to prevent stress points from developing.

Regular Inspections

Regular inspections are crucial for ensuring the longevity and safety of your rope chain. Inspecting for wear and tear at stress points is essential to prevent breakage. Regular cleaning and proper storage are also key to maintaining the integrity of the chain. Avoiding exposure to harsh chemicals and extreme temperatures is vital for preserving the material quality. Additionally, implementing a regular inspection schedule can help identify potential issues early, allowing for timely repairs or replacements. It's important to handle rope chains with care and attention to detail to ensure their longevity and durability.

Maintenance Tips:

- Inspect for wear and tear at stress points regularly

- Clean the chain with mild soap and water, and store it in a dry, cool place

- Avoid exposure to harsh chemicals and extreme temperatures

- Implement a regular inspection schedule to identify potential issues early

Conclusion

In conclusion, rope chains are a versatile and popular choice for jewelry and other applications. The strength of rope chains is influenced by various factors including material composition, weight bearing capacity, and durability. Understanding the types of rope chains, such as twisted, braided, and diamond-cut, provides insight into their unique characteristics. Factors affecting rope chain strength, such as material quality, manufacturing process, and usage conditions, play a crucial role in determining their reliability. Proper maintenance and care, including cleaning and storage, avoiding stress points, and regular inspections, are essential for ensuring the longevity of rope chains. Overall, rope chains can be strong and durable when the right materials and care are applied.

Frequently Asked Questions

Are rope chains strong enough for everyday wear?

Yes, rope chains are designed to be strong and durable for everyday wear.

Can rope chains support heavy pendants?

Yes, rope chains have a good weight-bearing capacity and can support heavy pendants.

How should I clean my rope chain?

To clean a rope chain, use a mild soap and warm water, and gently scrub with a soft brush. Avoid harsh chemicals.

Are twisted rope chains stronger than braided rope chains?

Both twisted and braided rope chains are strong, but the strength may vary based on the material and construction.

Do rope chains require regular maintenance?

Yes, it's important to regularly inspect and clean rope chains to maintain their strength and durability.

Can rope chains withstand moisture and humidity?

Rope chains made from high-quality materials can withstand moisture and humidity, but it's still best to avoid prolonged exposure to water and humidity.

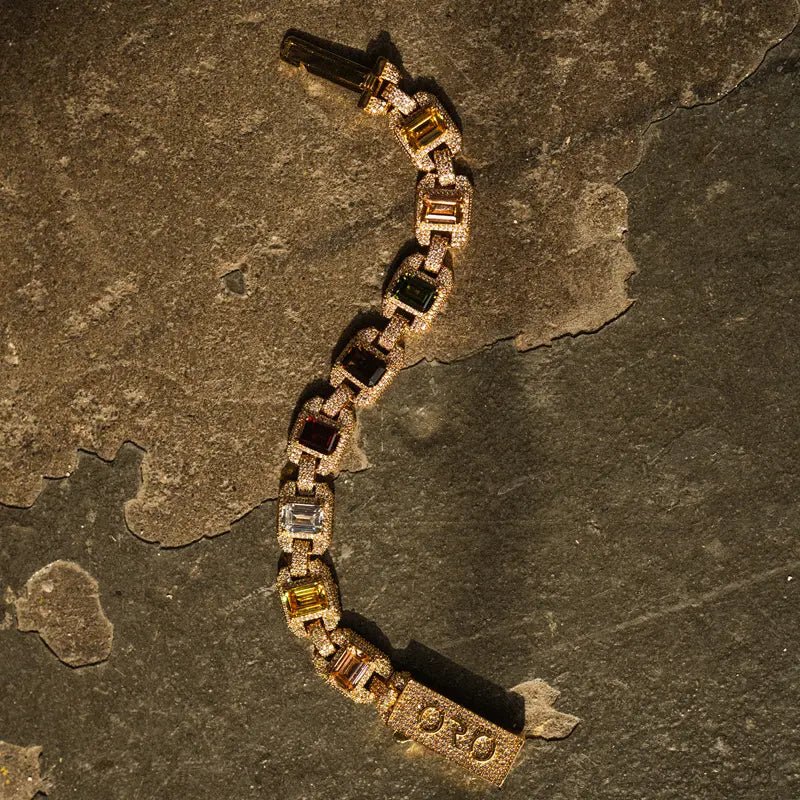

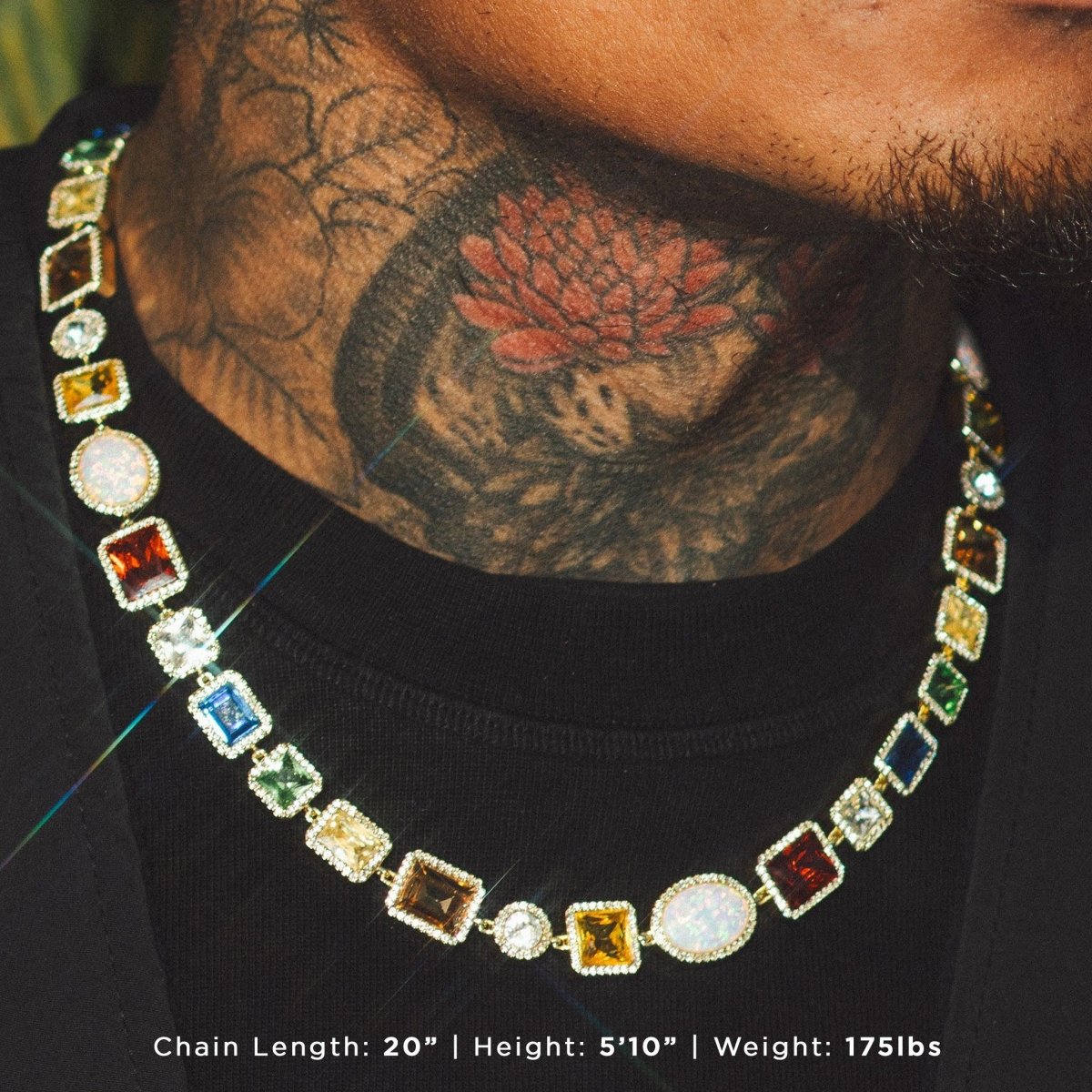

Best Sellers

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.